Contact us ?

Plot no. 5,

Parmeshwar Industrial Estate.

Near Ambe Mata Temple,

Dhamatvan - 382435.

+91 9428599429

Applications:

- Pipe Plant

- Lamination Plant

- Sheet Plant

- Monofilament Plant

- Blown Film Plant

- Blow Moulding Plant

- Sutli Plant

- Co-extrusion Plant

- Pen Plant

Advantages:

- It will filter Melt Material impurities and prevent die damages which will increase extruder life.

- Final Product quality will improve.

- It is hydraulic operated so, operator can change the mesh quickly and save time and energy both.

- Zero Leakage.

- Suitable for high pressure material flow.

- Save idle time hence production will increase.

- Easy to operate.

Optional Requirements:

- Barrel side and die side Flange/Adaptors along with heaters & fasteners.

- Accumulator Power pack with operating panel for fast movement.

- Pressure Transducer with cable and panel.

- Extra cartridge heaters.

- Extra Wire Mesh.

- Extra Breaker plate.

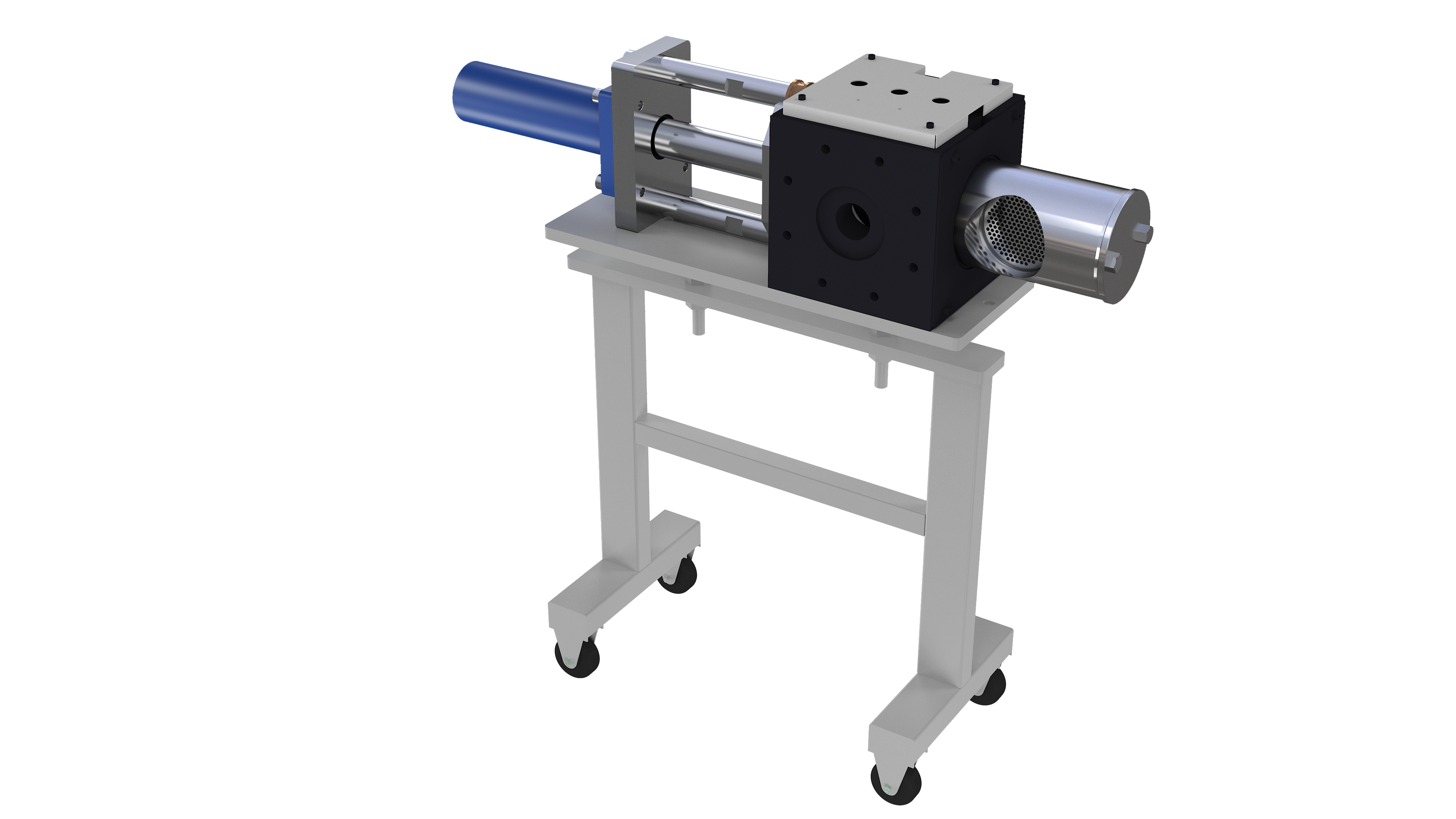

- Heavy duty simple support / wheel mounted trolley stand for screen changer support.

- Heating panel for screen changer heaters connection.

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time